|

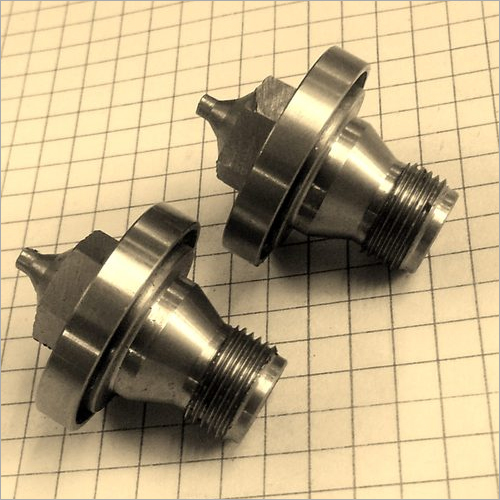

The manufacturing plant of the company is highly advanced and is facilitated with latest machinery like CNC lathes, CNC machines, automats and many other advanced precision machines to manufacture the components. We believe in efficiency at all levels of production; therefore we have installed the most sophisticated machines and deployed the most talented manpower to supervise the functioning of the production process.

Our workforce comprises of well qualified engineers, quality personnel and dedicated workmen. Kay Automatics Pvt. Ltd. deals in all kinds of well engineered components and parts matching the international standards of quality. The company is also fully equipped with advanced inspection equipments.

Facilities

In

the last 20 years, we have gathered a great wealth of knowledge and

experiences to develop complicated precision components and are well

versed with all forms of machining activities related to precision

machined & turned components. We are also equipped for complete

assemblies.

We have always tried to overcome the hurdles and

achieve success; hence we have been successful in achieving tolerance in

microns. We can also re-engineer the component submitted to us and thus

substitute imports. We can also provide complete assemblies and help

you with the supply management chain.

We intend to be a one stop shop for all your engineering requirements.

We

can assure you of our efforts toward the development of your product in

terms of machining activities related to it and willingness to invest

if required towards further development.

Processes carried out at KAPL include Machining, Milling, Slotting, Drilling, Boring, Threading, Tapping, Turning, Grinding, and Assembly.

Machines used include CNC Turning Centres, CNC Linear Chucker, Lathes, Centreless Grinder, Cylindrical Grinders, Thread Rolling, Drillings, Millings, and Tappings.

Inspection Equipments include Profile Projector, Height Gauges, Micro Metres, Vernier Calipers, Plug Gauges, Ring Gauges, Customised Gauges, and Dial Gauges.

Quality Policy

To

Achieve Complete Customer Satisfaction through Technological

Excellence, Continuous Improvement, Adherence to System and Procedure

with Active Employees Participation.

Certification

The company has been maintaining ISO 9001-2008 certification for the last six years.

- Certificate No.: QMS / CO717 / 0566

- Certifying Agency: Integrated Quality Certification Pvt. Ltd.; Accredited by NABCB.

Assured Quality

We

are an ISO 9001:2008 certified company. Quality in products comes

through standard production techniques and skills. Kay Automatics Pvt.

Ltd. has a well equipped in-house quality testing center where latest

testing equipments are used by our expert quality personnel. Our Quality

Control procedures are well defined and thoroughly implemented. We

follow various inspection procedures as follows:

- Incoming Inspection: Incoming Raw Materials are the foundation for the final product. We make sure that we start with the best raw materials. Raw Materials are inspected for:

- Dimensional parameters as defined e.g specified dimensions, roundness, straightness, etc.

- Chemical Properties through spectro analysis

- Surface Quality as required

- In-Process Inspection: In-Process Quality Control Procedures are defined to the minutest details in operator guidance sheets and are recorded in inspection records. These procedures enable operators, supervisors and quality control inspectors to produce the best quality products. Our production team is at the core of the quality assurance system. In-process Materials are inspected for:

- Dimensional properties such as dimensions" distribution in the tolerance range affecting Cp and Cpk values, ovalities, roundness, etc. as required.

- Outer Finish as required

- Finished Goods Inspection: The quality assurance team is also responsible for finished goods - we call it Final inspection. They inspect materials from the customers perspective. Our finished product must comply with our customers requirement as per following parameters.

- Dimensional properties such as dimensions" distribution in the tolerance range affecting Cp and Cpk values, ovalities, roundness, etc. as required in the customer drawings and control plans

- Packing, and Labelling

- Raw Material test reports attached with final inspection reports to be sent along with all supplies.

|

|

KAY AUTOMATICS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |